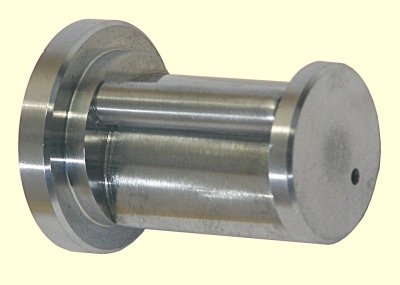

Woodturner's Pin chuck

This grips into a drilled hole. It is ideal for initial mounting of bowl blanks particularly natural edge blanks or irregular pieces which present no flat surface to which a faceplate can be screwed.

This grips into a drilled hole. It is ideal for initial mounting of bowl blanks particularly natural edge blanks or irregular pieces which present no flat surface to which a faceplate can be screwed.Old style pinchucks used a small loose pin which rolled on a machined flat. This did not work too well as the pin was too small and crushed into the wood. It could easily fall off into the shavings.

- Our much improved pinchuck shown uses a much larger pin which rolls on a cam shaped surface

- The pin has a spring loaded ball at one end to keep it from falling off

- The larger pin gives a much more secure grip

- Grips firmly into a 1,1/2" hole

First a hole is drilled to match the size of the pinchuck. The pinchuck is mounted on the lathe with the pin central at it's lowest point. The wood is pushed on by hand and twisted to lock. Untwist to unlock. What happens is that the pin rolls until it jams in the hole to lock the pinchuck in the wood.

First a hole is drilled to match the size of the pinchuck. The pinchuck is mounted on the lathe with the pin central at it's lowest point. The wood is pushed on by hand and twisted to lock. Untwist to unlock. What happens is that the pin rolls until it jams in the hole to lock the pinchuck in the wood.