Microcrystalline grinding wheels for sharpening woodturning tools

They self sharpen as they grind, wear slowly and require minimal dressing. They can last up to five times longer than a white wheel so they are well worth the extra money.

They will comfortably outperform white, red, pink or blue fused aluminium oxide wheels and of course they are light years ahead of those awful grey wheels which come on cheap grinders.

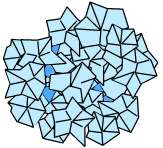

Micro crystal grit is made using radical new ceramic technology which is revolutionising the abrasives industry. Each grain of grit is actually a clump of hundreds of tiny crystals sintered together. The crystals continuously break away in use exposing thousands of fresh sharp microscopic cutting edges. Because the crystals are so small and numerous the finish on the steel is as good as from a very much finer wheel. The edge you get is almost as good as that from a wet grinder but obtained very much quicker. The cutting is so fast and cool you can quickly re-shape a tool without burning the steel. It works on carbon steel as well as HSS and you can even (with care) sharpen the thin edge of a carpenter's chisel. Try that with a conventional wheel!

|

Conventional abrasive is made from crystals which may or may not fracture under pressure and break down into smaller ones as the edges blunt. Blunt abrasive rubs and overheats your tools. |

|

Microcrystalline abrasive is made up from tiny clumps of hundreds of tiny sharp crystals. The crystals ("microcrystals") continually break away as they are used exposing millions of fresh sharp cutting edges. These cut cool and leave a fine finish on your tool bevel. The quality of the cutting edge produced is superb. |

The shop is now closed.You cannot buy microcrystalline wheels on this website. However you can buy similar wheels from The Toolpost here The Toolpost

This page updated Oct 2016 Back to home page

Sharp tools = enjoyable woodturning

Sharp tools = enjoyable woodturning